Short description

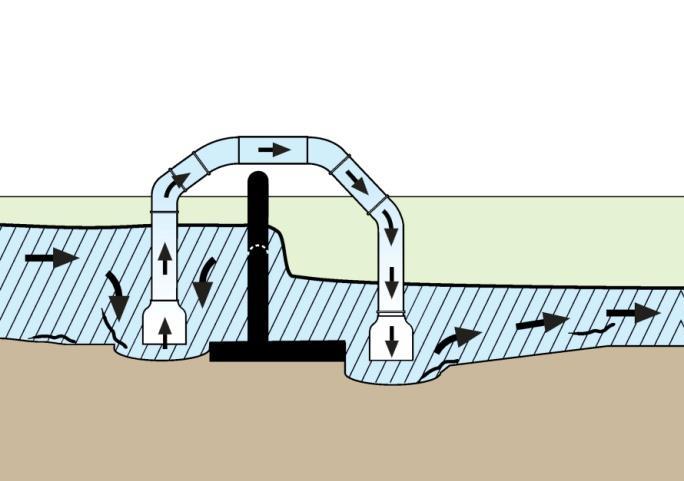

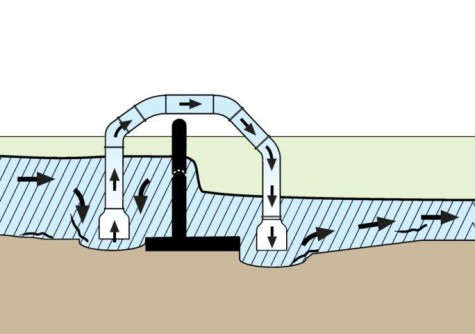

The siphon fish pass to be developed as part of the cooperation project offers a new solution for fish ways (ascent and descent) in the tightest of spaces and has low structural complexity com-bined with its compactness. This fish pass, designed according to the hydraulic siphon principle, uses modular pipe segments to bypass smaller transverse structures. The pipeline functions as a hydraulic siphon system, which is dimensioned in such a way that fish can swim through the pipe-lines in both directions without damage. On the one hand, there must be sufficient negative pres-sure in the pipe system to keep the suction effect going. On the other hand, however, the flow rate and flow velocities should be so low that macrozoobenthos organisms and fish willing to migrate upstream and downstream can use the siphon pipe as a passage corridor.

The aim of the research project is to develop and commission a prototype in the hydraulic engi-neering research laboratory. The requirements for the siphon fish pass described above give rise to a large number of hydraulic engineering and control technology issues. These include, in particu-lar, the process for automatic filling of the siphon line and air doping to regulate the flow velocity. These operating modes each require individual technical solutions, so that experience must first be gathered regarding the hydraulic conditions.

The essential properties of the siphon pipe and the decisive operating conditions are currently be-ing investigated by means of preliminary tests on a physical model in the hydraulic engineering research laboratory in order to develop and test possible technical solutions for the key processes. Following the preliminary tests, a small-scale laboratory model will be set up to investigate the hydraulic properties. The findings will be used to develop a real-scale prototype.